|

|

|

|

|

|

|

|

|

|

|

|

My profile

Learn more about me

Learn more about me

and my activities

Personal:

- Born in 1941

- married since 1974 with Ulrike, Dentist

- 1. daughter Franka Elsbett Klumpers,

Business economist

- 2. daughter Dr. Katrin Blanck, Veterinarian

- 4 grandchildren

My family (from left):

My family (from left):

- Eva, daughter of Franka and

Marco

- My wife Ulrike

- My daughter Franka

- Lars, son of Katrin and Nico

- Tom, son of Franka and Marco

- Marco, husband of Franka

- Carina, daughter of Katrin and

Nico

- Myself

- My daughter Katrin

- Nico, husband of Katrin

Education:

- Apprenticeship metalworker, Huettenwerke

Salzgitter

- Training as a technical designer in my father's company ELSBETT-MOTORS,

Salzgitter

- Parallel: Evening school in Nuremberg, Technical Diploma

- Study of Mechanical Engineering, Nuremberg

After 1963:

Foundation of engineering company

ELSBETT-KONSTRUKTION, based in Nuremberg

- First designs for new engine technologies

- Registration of my first patent: concept

of an opposed piston engine

- My father, Ludwig Elsbett (died in 2003), terminates at MAN after

6 years as a senior engineer and joins my company ELSBETT KONSTRUKTION. The

company MAN pays him licenses for the MAN-HM technology he developed. He

buys an industrial property and we relocate the company’s headquarter to

Hilpoltstein, near Nuremberg. Together, we are now building the company as

an institute for research and development on combustion engines

- In the beginning only engine developments on behalf of MAN are carried

out, as we are bound exclusively to this company for 3 years

- I have developed and manufactured measuring devices, e.g. a swirl

test

stand, an automatic fuel consumption measuring system and I also

build a

mechanical workshop, initially equipped with a lathe and a milling

machine

only. Thus, I am already producing improved engine components for

tests, e.g. steel pistons, which are centrally fixed on the

piston pin by a screw.

- In 1968, the first employees can be hired, the

workshop is enlarged and test stands for truck engines are designed and set

up by me

- From

1969

onward:

In the following years, many patent applications

have been filed.

Today, I am the inventor or co-inventor of some

hundreds of property rights.

A list can be found here

on the website of the Patent Office. In the Applicant / Inventor mask,

type only the name "Elsbett": You will then find more than 450 registered property rights.

After expanding the company and joining of my

brother Klaus Elsbett, the family owned company ELSBETT KONSTRUKTION is

picking up economic revival:

- New construction of a round hall with a

diameter of 40m. Here, test parts and complete engines can be manufactured.

I am responsible for the acquisition of more than 200 machines in the

following years - many of them CNC-controlled. Also special tools and

devices are designed by me. I have calculated the statics of the inwards

inclined hall roof so that test vehicles can travel up to 3 tons in a

circle without being seen from the outside

- set up a production line for small-scale production at least with the

employment of more than 80 highly qualified employees

- Under my direction, the design office has been converted to CAD

technology

- I plan and lead the construction of a fully automatic production line for

the steel pistons which were developed by ELSBETT

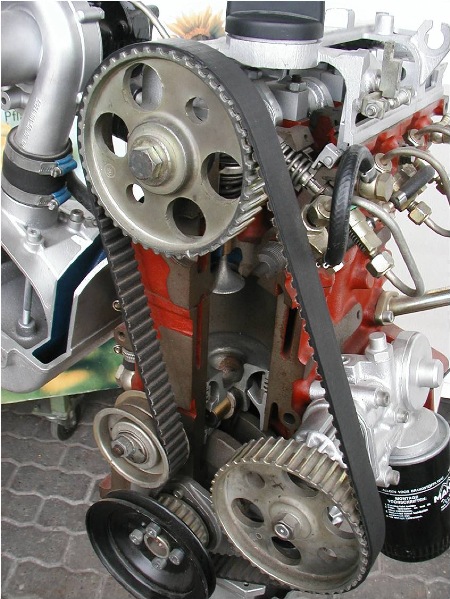

- Development and production of the engine known as the Elsbett engine, the world's first direct-injection

diesel for passenger cars in production. For this purpose, I have developed an injection system integrated in the cylinder head

with a fully variable mechanical control system, which offers a previously

not possible range of control possibilities. At the World Congress for

Automotive Engineers FISITA 1984 in Vienna, I present this technique to a

wide range of experts during a lecture at the Hofburg in Vienna.

- Development and production of the engine known as the Elsbett engine, the world's first direct-injection

diesel for passenger cars in production. For this purpose, I have developed an injection system integrated in the cylinder head

with a fully variable mechanical control system, which offers a previously

not possible range of control possibilities. At the World Congress for

Automotive Engineers FISITA 1984 in Vienna, I present this technique to a

wide range of experts during a lecture at the Hofburg in Vienna.

- The

Korean company Hyundai bought a license of the Elsbett technology including

combustion process and steel pistons. A team of three Korean experts was

stationed in Hilpoltstein for one year and was instructed and trained by me in

our technology. Two passenger cars of the type “Hyundai Pony” were converted to

direct injection and tested over long distances in Germany by test drivers.

Unfortunately, it was not possible at that time to convince Bosch that diesel

direct injection in cars has a future, so that the project failed due to the

fact that Hyundai did not find a supplier for the necessary injection

technology. This situation changed later, after European companies also dealt

with car direct-injection engines.

- I also develop engines and engine components on behalf of German

automotive manufacturers, e.g. race-engine camshafts for BMW, which are designed

and manufactured by us

- research on alternative fuels, e.g. vegetable

oil, and, on this basis, the development and manufacturing of corresponding

engines (passenger cars, trucks, tractors, station operators, CHP combined

heat and power)

- VW / Audi acquires a license for the Elsbett direct injection engine and engages

me for the further development of the TDI for one year in Heilbronn

- I successfully carry out the design of an air-cooled two-cylinder engine for

a DEUTZ subsidiary company in France

1988:

- The Elsbett engine technology is more and more

international and binds my technical activity for longer stays abroad,

including:

- Planning of an engine production for passenger cars in Brazil

- Planning of an engine production for construction machines and tractors

in Argentina

- Under my management, a complete technical documentation is produced for an

engine production in Russia

- Planning of an engine production in India

- Development of the so-called SWATCH engine

(later SMART). For a few years I am cooperating with SMH in Biel,

Switzerland. The prototype is manufactured and tested in Hilpoltstein, TÜV

approval in Munich

1990.

The 10 kW Diesel Single cyl. engine integrated at that time some outstanding new technologies:

- Flywheel-Crankshaft gear ratio 2.5 : 1 for integrated leight-weight alternator

- Hydraulic valve actuation and variable timing

- Integrated mass balancing first and second order

- Steel pistons and Oil cooling (no water or air)

1990:

- After technical success in China I got the post

as a guest professor at the Chinese Jiangsu

University, Zhenjiang, Jiangsu Province

From

1993

onwards:

- In 1993, the company Elsbett Konstruktion became

financially turbulent and was sold. The Elsbett family retreats. Two years

later, the new owner filed for insolvency

- In 1995, I founded my own design office GET

Günter Elsbett Technology, which I still operate today

- Also in 1995, together with my brother Klaus Elsbett, I founded

Elsbett-Technologie GmbH in Thalmässing. After a few years, I decided to

leave the company, but still keep active as a consultant

- I design a single cylinder for operation with palm oil in 1996/1997,

spending several months at the Elsbett office in Kuala Lumpur

- Design of Stirling engines for EPAS GmbH,

Leipzig. Here I am busy for several years on about 3 days a week. I lead

the design and development and also become co-owner. Several Universities in Germany and private customers bought complete Stirling constructions running in combination with furnaces fired by wood pellets or running on solar energy-collecting receivers on roofs of buldings. Later - due to low commercial success - the EPAS company was sold to the very prosperous Austrian ENERGIEBIG, which is an innovative company in the field of photovoltaics.

Since

2002:

The growing demand in China for my know-how in the

field of engine technology is shifting my activities more and more to China:

- The engines designed by me have better fuel consumption, higher

performance and reduced emissions. For these efforts I receive numerous

awards in China

2003:

- In Leipzig, I am contacted by a group of

businessmen who want to develop the idea of an opposed piston engine (OPE)

for decentralized energy generation. I

am commissioned to create a feasibility study. In this I develop

a series of new techniques, mainly the possibility of a four-stroke

operation. However,

the many efforts to market this concept remain unsuccessful

-

In the hope that an implementation of the ideas will nevertheless be

possible one day, I work on this technology on my own expense. In

addition to the pursuit of my other activities, this leads to many new

technical ideas and developments and a large number of presentations for

many companies. Further

technical progress is being made as a result of these efforts:

-

Complete technical documentation including a complete CAD drawing set for an

OPE prototype

-

In order to explain the OPE functions mechanically better and to gain

practical experience, I first make some functional models in Chinese

workshops. The

first functional tests with the newly developed liner control system are

successful, but strongly hamper my other tasks. Therefore

I decrease the further development for time and cost reasons

2004:

- I am initiating a university partnership between

Jiangsu University and the Technical University Amberg-Weiden

- In this cooperation, a government-funded research project is successfully

carried out, with ships on the Yangtze River being equipped with vegetable-oil

engines. The corresponding engines of Chinese manufacturers are provided by

me from my Chinese partner-companies.

I conclude a consultancy agreement with "Binzhou

Piston", the largest piston manufacturer in China. At the symposium in Binzhou, all major Chinese engine

companies will be there. I have presented the history of ELSBETT piston development and explainded especially the technology of steel pistons at this conference.

2007:

- I am appointed "External Examiner" at Cardiff

University, Wales. My task is the examination and acceptance of PHD (Dr.)

theses in the field of physics (Thesis: Thermodynamic design of Stirling

engines)

- Before the Olympic summer games in Beijing, I am converting some YaXing buses to run on vegetable oil

From

2011:

- May 2011: Due to the efforts of my partner in opposed

piston engines (OPE), an English finance group paid him a down-payment for

a license and offers me a performance-related payment for the development

of a running GKM. As I assumed that the sum would cover my development

costs and losses by restoring my normal job, I rented a workshop and installed

a test bench to push the further development of the OPE to the desired goal

- December 2011: The prototype for functional tests is working well

- April 2012: Completion of the project by successful runs and durability tests

of the OPE prototype. I am getting the agreed payment of the potential

investor, which, however, leaps back when he does not find a company that

is seriously interested in this technology, although its function is now

proven

- OPE further developments, presentations and technical

elaborations now happen again at my own risk and expense

- May 2013: Presentation of my OPE concept at the

International CIMAC Congress in Shanghai

- More than a dozen patent rights for this GKM technology have been

developed by me within the outline data of this project

At

present:

- Continuing and further concentration of my activities

in China: consultancy contracts with several companies and teaching

activity, e.g. Jiangsu University, Nantong University.

- Annually approximately 8 trips and 120 days stay in China

- Parallel to this in Germany, currently at own risk: Further reduced work

for the opposed piston engine technology; The prototype, which was already made

for the duration of the function test, is presently being stored due to lack

of interest, but can be rebuilt on a test bench if necessary.

- I also develop some concepts for sustainable use of marine energy and

technologies to avoid the consequences of an oil spill (see projects)

Some

important

awards:

- Dissertation Award by Technical High-School,

Cordoba/Argentina (1988),

- Philip Morris Award „Challenge Future“, Germany

(1989),

- European Solar Prize by EUROSOLAR, Bonn / Germany

(1997),

- Huangshan Award, the

highest award for foreign experts in Anhui Province / Hefei / China (2011),

- Friendship Award as the highest award for

foreigners in China by Prime Minister Wen Jiabao, Beijing / China (2012)